If you’re staring at a fresh ball of clay and wondering what to throw next, I’ve got you. These wheel throwing ideas start with the classic forms you’ll use all the time, then build into more playful twists that keep the wheel feeling exciting.

Classic Everyday Mug With a Smooth Lip

This charming, wheel-thrown mug features a comforting, bulbous shape that fits perfectly in your hands. With its earthy speckled clay body and a clean, unglazed aesthetic that highlights the material’s natural beauty, it’s an ideal project for practicing consistent wall thickness and creating functional, everyday ware.

Step-by-Step Guide

Materials

- Speckled stoneware clay (approx. 1 lb/450g)

- Potter’s wheel

- Throwing sponge

- Pin tool

- Wooden rib

- Metal kidney rib

- Cutting wire

- Loop tool or trimming tools

- Bucket of water

- Bat

- Clear matte glaze or transparent gloss glaze

Step 1: Throwing the Form

-

Center the clay:

Start by slamming your wedge of speckled clay onto the bat. Using plenty of water and firm pressure, cone the clay up and down until it is perfectly centered and spinning without a wobble. -

Open the well:

Press your thumbs into the center to open the floor. Aim for a floor width of about 2.5 to 3 inches, compressing the bottom with your fingers to prevent future S-cracks. -

Pull the cylinder:

Begin your first pull, bringing the walls up evenly. Keep the rim slightly thicker than the walls to ensure strength. Perform two or three pulls until you reach a height of roughly 4 inches. -

Create the belly:

Gently push the clay outward from the inside using your fingers or a sponge while supporting the outside. Create a soft, rounded curve that starts just above the foot and tapers back in slightly at the rim. -

Refine the curve:

Use a flexible metal or wooden rib on the exterior while pushing from the inside to smooth out throwing lines and define that beautiful, bulbous shape. -

Smooth the lip:

Using a chamois or a tightly folded piece of plastic, gently compress the rim to make it rounded and smooth—this is crucial for a pleasant drinking experience. -

Cleanup and cut:

Use a wooden tool to trim away excess slip and clay from the base of the pot. Run your wire tool under the mug to release it from the bat, then set it aside to stiffen to leather-hard.

Lip Comfort

Pay extra attention to the rim thickness. The lip shouldn’t serve just as an ending point, but should be slightly tapered and rounded so it breaks the surface tension of liquids cleanly without dripping.

Step 2: Trimming and Handle Making

-

Trim the foot:

Once leather-hard, center the mug upside down on the wheel. Use a loop tool to trim away excess weight from the bottom, carving a defined foot ring that mimics the curve of the mug’s body. -

Pull a handle blank:

While the mug is still centered, grab a separate small lug of clay. Hold it in one hand and use wet fingers to pull a long, tapered strip of clay (the carrot method) until it’s the desired thickness. -

Shape the handle:

Lay the pulled strip on a board to curve into a ‘C’ shape. Let it stiffen slightly until it can hold its shape but is still flexible. -

Attach the handle:

Score the mug at the attachment points and score the ends of your handle. Apply a dab of slip or water. Note how the handle in the image attaches just below the rim and loops down to the lower third of the belly. -

Secure and wipe:

Press the handle firmly onto the body. Use a small modeling tool or your finger to smooth the seams where the clay meets. Wipe away any excess slip with a damp sponge for a clean transition. -

Dry slowly:

Cover the mug loosely with plastic to ensure the handle (which dries faster) and the body dry at the same rate. This prevents cracking at the joints.

Step 3: Finishing

-

Bisque fire:

Once bone dry, load the mug into the kiln for a bisque firing (usually to Cone 04 or 06, depending on your clay body). -

Glaze interior:

Pour a transparent or white liner glaze into the inside of the mug, swirl it around to coat evenly, and pour it out. Wipe the rim clean if you want the raw clay lip exposed. -

Exterior glazing:

For the look in the photo, you can actually leave the exterior unglazed if your clay is vitrified and food-safe at temperature, or dip the whole piece in a very thin, clear matte glaze to enhance the speckles without adding color. -

Wipe the foot:

Make sure to wipe the foot ring completely clean of glaze to prevent it from sticking to the kiln shelf. -

Final firing:

Fire the mug to maturity (Cone 5, 6, or 10, per your clay’s instructions) to bring out the toasty color of the stoneware and seal the clay body.

Dual-Texture Texture

Create a satisfying tactile contrast by glazing only the inside and the upper inch of the exterior rim, leaving the rounded belly as raw, sanded clay that feels warm in the hands.

Enjoy your morning coffee in a vessel that feels as good to hold as it is beautiful to look at

Straight-Sided Tumbler Cup Set

This set of four straight-sided tumblers features a modern, cylindrical silhouette that balances functionality with style. The design highlights the natural beauty of the clay body with an exposed base, contrasting beautifully against a speckled cream glaze.

Detailed Instructions

Materials

- Stoneware clay (speckled or buff)

- Pottery wheel

- Throwing sponge

- Wire tool

- Pin tool

- Wood or metal rib

- Trimming tools

- Speckled cream or matte white glaze

- Wax resist (optional)

Step 1: Throwing the Forms

-

Prepare your clay:

Wedge about 3-4 pounds of clay thoroughly to remove air bubbles. Divide this into four equal balls, weighing roughly 1 lb (approx. 450-500g) each for consistency across the set. -

Center specifically:

Place the first ball on the wheel head. Instead of centering wide and flat, focus on centering the clay into a taller, narrower mound to prepare for the cylindrical shape. -

Open the floor:

Drop your center hole, leaving about 1/4 to 3/8 inch of clay at the bottom. Pull the floor out flat until it is roughly 2.5 to 3 inches wide. Compress the floor well with your sponge or a wooden tool to prevent S-cracks later. -

Pull the walls:

Perform your first pull, bringing the clay up into a cone shape to keep it on center. For subsequent pulls, focus on lifting the walls straight up, keeping your inside and outside fingers directly opposite each other to maintain verticality. -

Refine the cylinder:

Aim for a height of about 4.5 to 5 inches. Use a wooden or metal rib on the outside while supporting the inside with your hand to remove throwing lines and straighten the profile, ensuring the walls are perfectly vertical without bowing out. -

Address the rim:

Using a chamois or your slightly wet fingers, gently compress and round the rim. A comfortable drinking edge is crucial for tumblers. -

Clean the base:

Use a wood knife or pin tool to undercut the base slightly, removing excess clay from where the pot meets the wheel head. This makes wire-cutting and lifting easier. -

Cut and repeat:

Wire the pot off the wheel and set it aside on a ware board. Repeat the process with the remaining three balls of clay, using a ruler or calipers to match the height and width of the first one.

Step 2: Trimming and Finishing

-

Wait for leather hard:

Allow the tumblers to dry slowly under plastic until they are leather hard. The rim should be firm enough to support the weight of the cup when flipped over. -

Trim the base:

Center a tumbler upside down on the wheel. Secure it with clay lugs. Trim the bottom and the lower 1/2 inch of the wall to create a clean, defined foot. This sharp line is where your glaze will eventually stop. -

Refine the surface:

If you want a very smooth raw clay texture at the bottom, lightly burnish the trimmed area with a smooth stone or the back of a spoon while the wheel spins slowly. -

Bisque fire:

Once fully bone dry, load the tumblers into the kiln for a bisque firing (typically Cone 04 or 06, depending on your clay).

Wobbly cylinders?

Walls often flare out due to centrifugal force. To correct this during throwing, do a ‘collar’ move: lubricate your hands and gently squeeze the rim inward to bring the shape back to a tight cylinder.

Step 3: Glazing

-

Prep for dipping:

Wipe the bisque-ware down with a damp sponge to remove dust. If you prefer a crisp line without dipping skill, apply wax resist to the bottom inch of the tumbler and the foot. -

Mix the glaze:

Stir your speckled cream glaze thoroughly. You want the speckles well-suspended so they appear evenly on the final cup. -

Dip the tumblers:

Using glazing tongs or your hand (if the interior is already glazed and dry), dip the tumbler straight down into the glaze. Stop about 1 inch from the bottom to leave that signature band of raw clay exposed. -

Clean and fire:

If you dripped any glaze onto the raw clay section or the foot, wipe it away cleanly with a sponge. Fire the pieces to maturity (likely Cone 5 or 6 for stoneware).

Level Up: Texture

Before the clay dries, gently press a piece of coarse linen or canvas against the upper walls. The glaze will break over the fabric texture, adding subtle visual interest to the smooth surface.

Enjoy using your new set for morning coffee or cool drinks

Beginner-Friendly Cereal Bowl With Throwing Lines

This charming, rustic cereal bowl features a warm, speckled cream glaze and a classic rounded form that fits perfectly in your hand. The subtle throwing lines left on the exterior add a tactile, handmade quality that highlights the craftsmanship without overwhelming the simple design.

How-To Guide

Materials

- Stoneware clay (preferably a buff or speckled clay body)

- Pottery wheel

- Bucket of water and sponge

- Wire cutter

- Needle tool

- Wooden or metal rib

- Loop trimming tool

- Cream or oatmeal speckled glaze (cone 5/6 typically)

- Kiln access

Step 1: Throwing the Form

-

Center the clay:

Start with about 1 to 1.5 pounds of clay. Slam it onto the center of the wheel head and use firm pressure with coned hands to center the clay until it spins smooth and vibration-free. -

Open the clay:

Press your thumbs into the center of the mound, pushing down until you are about a quarter-inch from the wheel head to leave enough thickness for the foot. -

Establish the floor:

Pull the clay outward towards your body to create a flat, even floor. Compress the floor with your fingertips or a sponge to prevent future S-cracks. -

First pull:

Using a pincer grasp, gently squeeze the clay wall and pull upward. Keep your speed steady and don’t worry about shape yet; just focus on gaining height and even wall thickness. -

Shape the bowl profile:

On your next pulls, apply slightly more pressure from the inside hand to push the wall outward, creating that gentle, rounded curve. I like to keep the rim slightly thicker than the walls for durability. -

Refine the rim:

Use a small piece of chamois or your sponge to compress and smooth the rim. A rounded, comfortable rim is essential for a functional eating vessel. -

Cut off:

Using a wire tool, slide it cleanly under the base of the bowl while the wheel is spinning slowly or stopped. Carefully lift the bowl off with dry hands or pot lifters and set it aside to reach leather-hard consistency.

Wobbly Rims?

If the rim starts to wobble during throwing, you might be pulling too fast or the clay is getting too thin. Slow the wheel down and compress the rim with a sponge to restabilize it.

Step 2: Trimming and Finishing

-

Center for trimming:

Once leather hard, place the bowl upside down on the wheel. Center it perfectly and secure it using three small lugs of soft clay. -

Define the foot ring:

Using a sharp loop tool, carve away the excess clay at the base to create a defined foot ring. The image shows a visible unglazed foot, so aim for a clean line where the glaze will stop. -

Trim the curve:

Shave off excess weight from the lower curve of the bowl, following the interior shape. Avoid over-smoothing the exterior if you want to keep subtle throwing rings visible. -

Smooth the foot:

Run a damp sponge or a smooth rib over the trimmed foot ring to remove any sharp burrs or rough edges from the trimming tool. -

Bisque fire:

Allow the bowl to bone dry completely, which may take several days depending on humidity. Load it into the kiln for the first bisque firing (usually cone 04 or 06).

Step 3: Glazing

-

Wax the foot:

Apply wax resist to the bottom foot ring and a few millimeters up the side wall. This ensures the clean, unglazed line seen at the bottom of the finished bowl. -

Prepare the glaze:

Mix your cream or oatmeal speckled glaze thoroughly. If the glaze is too thick, the speckles might get swallowed; if too thin, it may streak. -

Dip the interior:

Pour glaze inside the bowl, roll it around to coat the entire interior surface, and pour the excess out quickly. -

Dip the exterior:

Holding the bowl by the foot (or using glazing tongs), dip the exterior into the bucket, stopping right where the wax line begins. Hold for 3 seconds and lift. -

Clean up:

Once the glaze is dry to the touch, use a damp sponge to wipe any stray glaze droplets off the waxed foot area. -

Final firing:

Load the glazed bowl into the kiln and fire to the glaze’s maturity temperature (e.g., cone 5 or 6). Let the kiln cool naturally before unloading.

Make it a Set

Weigh your clay balls precisely before throwing. Using exactly 1.25 lbs for every piece helps ensure your bowls are identical in size, creating a professional-looking stackable set.

Enjoy your morning routine even more by eating out of a vessel created with your own hands

Low, Wide Pasta Bowl With a Gentle Rim

This rustic yet elegant pasta bowl features a satisfyingly wide, open form perfect for hearty meals. The design combines a speckled, creamy stoneware exterior with a deep, glossy ocean-blue interior, separated by a distinct brownish rim that frames the food beautifully.

Step-by-Step Tutorial

Materials

- Speckled stoneware clay (approx. 2-2.5 lbs)

- Pottery wheel

- Throwing bucket and sponge

- Wooden rib tool

- Metal kidney scraper

- Needle tool

- Wire cutter

- Trimming tools (loop tool)

- Glossy deep blue glaze

- Clear or satin matte glaze (optional for exterior)

- Wax resist

- Glaze brushes

Step 1: Throwing the Form

-

Center wide:

Begin by wedging your speckled clay thoroughly to remove air bubbles. Slam it onto the wheel head and center it into a low, wide puck shape rather than a tall cone, setting the foundation for the bowl’s width. -

Open the floor:

Open the clay down to about 3/8 inch thickness. Instead of pulling straight up, pull the clay out horizontally to establish a broad, flat floor. Compress this floor well with your sponge or a wooden rib to prevent S-cracks later. -

Pull the walls:

Pull the walls up and slightly outward. Since this is a pasta bowl, you want a shallow curve, not steep sides. Aim for a wall height of about 2.5 to 3 inches. -

Shape the curve:

Use a wooden rib on the inside to define a continuous, smooth curve from the center of the floor up to the rim. I like to push gently against the rib from the outside to create a tension that strengthens the wall. -

Define the rim:

Compress the rim with a chamois or your sponge. Keep the rim slightly thick and rounded to give it that durable, rustic look shown in the photo. -

Clean the distinct undercut:

Use a wooden knife tool to cut a small undercut at the base of the bat. This will make removing the pot easier and give you a guide for trimming later. -

Wire off:

Run your wire cutter under the pot and carefully slide the bat off the wheel. Allow the piece to dry to a leather-hard state.

Clean Rims

To get that crisp brownish rim line, dampen a sponge and wipe the very top edge of the rim immediately after dipping the blue glaze. This exposes the iron-rich clay beneath.

Step 2: Trimming and Drying

-

Center specifically for trimming:

Once leather hard, invert the bowl onto the wheel. Secure it with clay lugs or use a Giffin Grip. Tap it to ensure it is perfectly centered. -

Define the foot ring:

Trim away the excess clay from the lower outer wall to mirror the interior curve. Carve a distinct foot ring that elevates the bowl slightly, giving it a lighter presence on the table. -

Smooth the exterior surface:

Before flipping it back over, run a smooth metal rib over the trimmed area to burnish the speckled clay slightly. This makes the unglazed or lightly glazed exterior feel pleasant to the touch. -

Bisque fire:

Allow the bowl to dry completely (bone dry). Fire it in the kiln to a bisque temperature (usually cone 04 or 06, depending on your clay body).

Step 3: Glazing

-

Clean the bisque:

Wipe the bisque-fired bowl with a damp sponge to remove any kiln dust, which can cause glaze defects. -

Wax the foot:

Apply wax resist to the bottom foot ring and the very bottom center of the exterior. This prevents glaze from sticking to the kiln shelf. -

Pour the interior:

Pour a generous amount of glossy deep blue glaze into the bowl. Roll it around to coat the entire interior surface, then pour the excess out quickly. -

clean the rim immediately:

While the interior glaze is drying, wipe any drips off the rim. For the look in the photo, you want the rim to have a thinner application or be wiped back to expose the clay body slightly. -

Glaze the exterior:

Dip the exterior into a clear glaze, or leave it raw if the clay body is fully vitrified at high fire. The goal is to see those natural speckles. -

Create the ombre effect:

If you want the slight gradient seen in the photo near the bottom, you can lightly spray or brush a very thinned wash of the blue glaze near the bottom edge of the exterior, fading it upward. -

Final wipe:

Check the foot ring one last time to ensure no glaze is on the contact points. -

Glaze fire:

Fire the piece to the maturity temperature of your clay and glaze (typically cone 6 or cone 10) in an oxidation or reduction atmosphere as appropriate for your materials.

Slumping Walls?

If the wide walls start to droop while throwing, use a heat gun or torch for a few seconds on the lower walls to stiffen them up before shaping the final outward curve.

Now you have a stunning, functional piece of tableware ready to be filled with your favorite pasta dish

What Really Happens Inside the Kiln

Learn how time and temperature work together inside the kiln to transform clay into durable ceramic.

Snack Plate With a Clean, Wide Rim

These charming snack plates feature a classic wide rim and a speckled, earthy finish that highlights the beauty of handmade ceramics. The slightly elevated edge keeps crumbs contained while offering a modern, stackable silhouette perfect for casual dining.

How-To Guide

Materials

- Speckled stoneware clay (approx. 1.5 lbs per plate)

- Pottery wheel

- Throwing bat

- Bucket of water and sponge

- Needle tool

- Wood rib tool

- Wire cutter

- Trimming tools (loop tool)

- Cream or oatmeal matte glaze

- Iron oxide wash or dark brown underglaze

Step 1: Throwing the Form

-

Center the Clay:

Begin by firmly wedging your clay to remove air bubbles. Slam the ball onto the center of the wheel head or bat. Using a moderate wheel speed and wet hands, cone the clay up and press it back down until it runs perfectly smooth and centered. -

Open the Mound:

Press your thumbs into the center of the spinning clay, opening it wide rather than deep. Since this is a plate, you want a wide, flat floor immediately. Leave about 1/4 to 3/8 inch of thickness for the base. -

Establish the Floor:

Compress the floor by moving your fingers or a sponge from the center out to the right (at 3 o’clock). Repeat this several times to prevent S-cracks later. The floor should be flat and consistent. -

Define the Rim:

Instead of pulling a tall wall, focus on a thick, low outer ring. Pull this clay outward and upward slightly to create a distinct transition between the flat eating surface and the vertical rim. -

Shape the Wall:

Pull the low wall up to about 3/4 of an inch high. Keep the rim thick and sturdy rather than tapering it too thin, as this matches the rustic aesthetic. -

Refine with a Rib:

Take a wooden rib tool and compress the flat eating surface one last time to ensure it is dead flat. Then, use the rib to smooth the vertical wall, giving it a sharp, clean definition at the breakage point where the floor meets the wall. -

Finish the Lip:

Use a chamois or a very slightly damp sponge to round off the top lip of the rim so it isn’t sharp to the touch. -

Cut and Dry:

Run your wire tool under the plate to separate it from the bat. Leave it on the bat to dry significantly slowly until it reaches a leather-hard state.

Plate Warping?

Plates often warp if dried unevenly. Dry them slowly away from drafts, flipping them rim-to-rim periodically, or weight the centers lightly with a sandbag while drying.

Step 2: Trimming and Glazing

-

Secure for Trimming:

Once leather hard, center the plate upside down on the wheel. Secure it with small coils of clay or a trimming chuck if necessary. -

Trim the Foot:

Using a sharp loop tool, carve away excess clay from the bottom. Create a distinct foot ring that mirrors the vertical wall on the top side. This lifts the plate and gives it a professional shadow line. -

Smooth the Surface:

After trimming, run a damp sponge or a smooth rib over the trimmed area to erase tool marks and compress the grog back into the clay body. -

Bisque Fire:

Allow the plates to bone dry completely, then load them into the kiln for a bisque firing (usually Cone 06 or 04). -

Apply Main Glaze:

Wipe the bisque ware with a damp sponge to remove dust. Dip or pour your cream/oatmeal matte glaze over the entire piece. I find that dipping ensures the most even coverage for plates. -

Clean the Foot:

Immediately wipe the foot ring clean with a sponge so the plate won’t stick to the kiln shelf. -

Accent the Rim:

Dip a brush into iron oxide wash or a thin dark brown underglaze. While holding the brush steady against the rim, spin the wheel (or a banding wheel) to apply a consistent brown band to the very edge. -

Glaze Fire:

Fire the plate to the maturity temperature of your clay and glaze (likely Cone 5 or 6 for stoneware). Let the kiln cool naturally before unloading.

Matching Set

To make a matching stack, use a simple ruler or gauge stick while throwing. Measure the width of the floor and height of the rim for the first plate, and match every subsequent ball of clay to those marks.

Stack your new set on open shelving to show off those beautiful, crisp edges

Bud Vase With a Narrow Neck (Collaring Practice)

This project features a classic bulbous bud vase with a narrow neck, perfect for displaying a single stem or a small dried arrangement. The speckled clay body and minimal glaze create a rustic, organic feel that highlights the throwing rings near the base.

How-To Guide

Materials

- Speckled Stoneware Clay (e.g., Laguna Speckled Buff)

- Pottery Wheel

- Medium throwing sponge

- Wooden throwing rib

- Metal kidney rib

- Wire cutter

- Needle tool

- Chamois leather strip

- Clear or Satin Matte Glaze (transparent)

Step 1: Throwing the Base Form

-

Prepare and center:

Start with a manageable ball of speckled clay, about 1 to 1.5 pounds. Wedge it thoroughly to remove air pockets, then slam it onto the wheel head. Center the clay into a low, wide puck shape rather than a tall cone. -

Open the clay:

Open the centered clay, going down until you have about a quarter-inch of floor thickness. Establish a flat bottom inside, but keep the floor relatively narrow, as the belly will swell out from here. -

Initial pulls:

Begin pulling the walls up into a cylinder. Don’t worry about the curve yet; just aim for even wall thickness. Leave a slightly thicker rim of clay at the top to support the necking process later. -

Shape the belly:

Once you have height, use your inside hand to push the clay outward while your outside hand supports it gently. Create a round, bulbous shape, keeping the widest point relatively low to match the reference image. -

Refine the curve:

Use a wooden rib on the outside to refine the curve of the belly. This compresses the clay and removes excess slurry, making the walls stronger for the next step.

Torquing Neck?

If the clay starts twisting during collaring, you’re creating too much friction. Use more water or slip, and reduce the surface area of your hands touching the clay at once.

Step 2: Collaring and Necking

-

Begin collaring:

This is the core of this project. Wet your hands and the clay rim. Place your hands around the top opening like a butterfly, thumbs touching and fingers wrapped around. Gently squeeze inward while the wheel spins to narrow the opening. -

Pull and collar again:

After your first collar, the clay at the neck will thicken. Perform a small, careful pull on just this upper section to thin it out and gain height. Then, collar it in again. -

Repeat until narrow:

I usually repeat the collar-and-pull sequence three or four times. Continue until the neck is about an inch wide or less. Be patient; rushing this can cause the clay to torque or collapse. -

Flare the rim:

Once the neck is sufficiently narrow, use the pad of your finger to gently flare the very top rim outward, creating that delicate lip seen in the photo. -

Compress the rim:

Use a damp strip of chamois leather held over the rim. spin the wheel and gently press down to smooth the lip and ensure it’s round and pleasant to the touch.

Pro Tip: Height Check

Don’t trim the neck too short. Leave extra height during the throwing stage, as collaring actually thickens the wall, allowing you to pull it taller than you expect.

Step 3: Finishing and Glazing

-

Add texture:

While the wheel is spinning slowly, use the corner of your wooden tool or a stiff finger to accentuate the throwing rings near the bottom of the pot. These ridges catch the glaze beautifully. -

Trim the foot:

Once leather hard, trim a neat foot ring on the bottom. This lifts the form and gives it a professional finish. -

Bisque fire:

Fire the piece to cone 04 (or your clay’s specific bisque temperature). -

Glaze application:

Dip the entire piece into a clear or satin matte transparent glaze. Since you used speckled clay, the ‘decoration’ is already built into the clay body. The transparent glaze will reveal those beautiful iron spots. -

Iron oxide rim (optional):

To match the reference perfectly, dip just the very rim into a slightly darker glaze or brush a tiny amount of iron oxide wash on the lip for that toasted edge look. -

Final firing:

Glaze fire to maturity (likely cone 5 or 6). Once cool, the speckles will have bled through the white glaze, creating the finished texture.

Now you have a charming vessel ready to hold your favorite dried botanicals

The Complete Guide to Pottery Troubleshooting

Uncover the most common ceramic mistakes—from cracking clay to failed glazes—and learn how to fix them fast.

Bottle Vase With a Long, Elegant Neck

This classic bottle form features a bulbous base that tapers gracefully into an elongated neck, offering a perfect canvas for texturing. The earthy tri-tone finish mimics the look of layered sediment, creating a warm, organic feel ideal for dry botanical arrangements.

Step-by-Step Tutorial

Materials

- Stoneware clay (with grog for stability)

- Pottery wheel

- Throwing sponge

- Needle tool

- Metal kidney rib

- Wire cutter

- Wooden throwing stick (optional)

- White matte glaze

- Rust/terracotta dipping glaze or oxide wash

- Wax resist

Step 1: Throwing the Base Form

-

Center and Coning:

Begin with about 2-3 lbs of well-wedged clay. Center it firmly on the wheel head, coning up and down twice to align the clay particles, which helps support the tall neck later. -

Opening the Floor:

Open the clay to create a floor about 3-4 inches wide. Compress the bottom thoroughly with a rib to prevent s cracks. -

Pulling the Cylinder:

Pull up the walls into a tall, even cylinder. Focus on keeping the walls consistent in thickness from bottom to top; leave slightly more clay near the bottom for stability. -

Belling the Body:

Using inside pressure, gently push the belly of the pot outward from the inside. Create a rounded, bulbous shape in the bottom third of the vessel, but keep the top section relatively straight for now.

Collaring Cracks?

If the neck ripples or twists while collaring, the clay is too dry or the wheel is too slow. Keep the clay wet and speed up the wheel slightly for smoother compression.

Step 2: Collaring the Neck

-

First Collar:

Lubricate the outside of the upper cylinder heavily. Using both hands (thumbs touching), gently squeeze the clay inward while the wheel spins to narrrow the opening. Do this gradually. -

Pulling for Height:

After the first collar, perform a small pull on just the neck section to thin it out and add height. This prevents the clay from getting too thick as you compress it inward. -

Refining the Shape:

Continue collaring and pulling alternately until you achieve a long, slender neck. I find using a throwing stick inside the neck helps keep the interior wall straight if my fingers no longer fit. -

Creating Texture:

While the wheel spins slowly, use the serrated edge of a metal rib or a trimming tool to create horizontal texture bands around the middle section of the vase, leaving the very bottom and top smooth. -

Rim Finishing:

Compress the rim with a chamois or sponge. Create a slight outward flare at the very top for visual balance.

Textured Gradient

Apply wax resist over the textured middle band before dipping the top color. The wax will create a crisp separation, highlighting the raw clay texture between glaze layers.

Step 3: Trimming and Glazing

-

Drying to Leather Hard:

Allow the piece to dry slowly to a leather-hard state. Because of the thin neck, cover the top with plastic to keep it from drying out before the base. -

Trimming the Foot:

Center the pot upside down (using a chuck if the neck is too long/fragile). Trim a tidy foot ring and refine the curve of the bulbous bottom. -

Bisque Fire:

Once fully dry, bisque fire the vessel according to your clay body’s specifications. -

Base Glazing:

Pour a speckled white matte glaze inside the vase to coat the interior. Then, dip the bottom third of the exterior into the same white glaze. -

Middle Accent:

Brush a light iron wash or a translucent tan glaze over the textured middle band. Wipe it back slightly with a damp sponge so the color sits deep in the carved grooves. -

Top Section:

Dip the top neck section into a rust or terracotta glaze, overlapping slightly with the middle band to create a soft transition. -

Final Fire:

Clean the foot perfectly and glaze fire the piece to cone 6 (or your clay’s maturation temperature).

This elegant silhouette looks stunning on a mantelpiece even without flowers

Simple Planter With a Matching Saucer

This project features a clean, cylindrical planter with a subtle texture and minimalist decoration that lets the clay body shine. The matching saucer isn’t just functional; its slightly raised rim and matching glaze turn the set into a cohesive piece of home decor.

Step-by-Step

Materials

- Speckled stoneware clay (approx. 2-3 lbs)

- Pottery wheel

- Throwing sponge

- Pin tool

- Wire tool

- Rib tool (metal or wood)

- Trimming tools

- Semi-transparent creamy white glaze

- Wax resist (optional)

- Loop tool for texture (optional)

Step 1: Throwing the Planter

-

Center the clay:

Start with about 1.5 to 2 lbs of speckled clay. Secure it to the wheel head and center it into a low mound. -

Open the floor:

Drill down into the center, stopping about 3/4 of an inch from the bat to leave enough thickness for the base. Widen the opening to your desired interior diameter—about 4-5 inches works well for this size. -

Pull the walls:

Pull the clay upward to create a cylinder. Focus on keeping the walls straight and vertical, avoiding the tendency to flare outward. You want a consistent thickness from bottom to top. -

Refine the shape:

Use a metal or wooden rib on the outside while supporting the inside with your hand. Compress the outside wall to create a smooth, straight-sided profile and remove excess slurry. -

Shape the rim:

Use a chamois or your sponge to gently compress and round the rim. A slightly thickened rim adds visual weight and durability. -

Cut underneath:

Use a wooden knife tool to undercut the base slightly, creating a guide for where you will trim later. Wire the pot off the bat and set aside to dry to leather-hard.

Wobbly Walls?

If your cylinder walls are twisting during the pull, you might be moving your hands up faster than the wheel speed allows. Slow your upward movement or speed up the wheel slightly.

Step 2: Throwing the Saucer

-

Flatten the clay:

Take a smaller amount of clay (about 0.5-0.75 lb) and center it low and wide, like a pancake. -

Create the rim:

Open the clay slightly but focus on spreading it horizontally. Pull up a short, steep rim—about 1 inch high—to catch water overflow. -

Refine the curve:

Use a rib to smooth the interior curve, ensuring it’s flat enough in the center to hold the pot stably. Measure against your planter’s base to ensure a good fit. -

Wire off:

Wire the saucer off the bat and let it firm up alongside the planter.

Raw Clay Contrast

Instead of just carving, brush a little iron oxide wash into the carved grooves before waxing. This will darken the raw stripes and make the texture pop against the white glaze.

Step 3: Trimming and Decorating

-

Trim the planter base:

Once leather-hard, center the planter upside down on the wheel. Trim excess weight from the bottom and carve a foot ring if desired, or keep a flat bottom with a slight bevel. -

Add the drainage hole:

Don’t forget this crucial step! Turn the pot right-side up and use a hole cutter or drill bit to create a drainage hole in the center. -

Carve the stripes:

While the pot is spinning slowly on the wheel (or a banding wheel), use a small loop tool or a serrated rib to carve three distinct bands around the lower third of the pot. Vary the pressure to create that rough, raw clay texture. -

Trim the saucer:

Trim the underside of the saucer to mirror the style of the pot. I like to smooth the edges with a damp sponge to remove any sharp burrs.

Step 4: Glazing

-

Bisque fire:

Fire both pieces to cone 04 (or your clay’s specified bisque temperature). -

Apply wax resist:

Wax the bottom of the pot and the saucer. Carefully apply wax over the three carved texture bands if you want the raw clay to show through, as seen in the photo. -

Dip into glaze:

Dip the planter and saucer into a semi-transparent white or cream glaze. The transparency allows the natural speckles of the clay to show through. -

Clean up:

Wipe away any glaze beads from the waxed areas with a damp sponge to ensure clean lines. -

Glaze fire:

Fire to the maturation temperature of your clay and glaze (likely cone 5 or 6 for stoneware).

Plant your favorite succulent inside and enjoy the organic warmth this set brings to your shelf

TRACK YOUR CERAMIC JOURNEY

Capture glaze tests, firing details, and creative progress—all in one simple printable. Make your projects easier to repeat and improve.

Utensil Crock With a Thick, Durable Rim

This classic utensil crock combines functionality with rustic charm, featuring a speckled cream glaze and a distinctively thick, doubled rim. The visible unglazed clay at the base adds a beautiful warm contrast that grounds the piece.

Step-by-Step Tutorial

Materials

- Stoneware clay (speckled or buff)

- Potter’s wheel

- Medium throwing bat

- Bucket of water

- Sponge

- Wooden rib tool

- Needle tool

- Wire cutter

- Trimming tools

- Speckled cream or oatmeal glaze

- Wax resist

Step 1: Throwing the Cylinder

-

Center the clay:

Start with about 3-4 pounds of wedged clay. Slam it onto the bat and center it using firm pressure. You want a wider base for this project to ensure stability when it’s filled with heavy utensils. -

Open the form:

Open the centered mound, leaving the floor about half an inch thick. Compress the floor thoroughly with your fingers or a flat tool to prevent S-cracks later. -

Pull the walls:

Being your pulls, bringing the clay up into a tall, straight cylinder. Aim for even thickness, but leave a bit more clay at the very top rim than usual—we will need this extra material for the folded detail. -

Shape the profile:

Use a wooden rib on the outside against your hand on the inside to straighten the walls. The crock in the photo is nearly perfectly vertical, perhaps tapering in just slightly at the top.

Slumping Walls?

If your cylinder walls start to warp or slump, you likely pulled them too thin or used too much water. Use a heat gun to stiffen the clay slightly before attempting the rim fold.

Step 2: Creating the Double Rim

-

Prepare the rim:

Chamois the top edge so it is smooth. Now, using your needle tool or a wooden knife, create a deep groove about 1 inch down from the lip on the outside. Do not cut all the way through. -

Fold the clay:

Alternatively, you can throw a tall, thin flange at the top and physically fold it over outward. To match the image exactly, I prefer to fold the clay over to create that thick, rounded band. -

Secure the fold:

Once folded, gently compress the new double-thick rim against the wall. Use the rounded side of your wooden tool to define the bottom edge of the rim, creating that distinct shadow line seen in the photo. -

Refine the surface:

Do a final pass with a sponge to smooth any finger marks, ensuring the speckles in the clay (if using speckled clay) are pushed flush with the surface.

Step 3: Trimming and Glazing

-

Wire off and dry:

Run a wire under the pot and let it dry to leather hard. This usually takes a day or two depending on humidity. -

Trim the base:

Center the leather-hard piece on the wheel. Trim the bottom to create a clean foot. To match the image, trim a slight bevel at the very bottom edge where the glaze will stop. -

Bisque fire:

Once fully bone dry, fire the piece to bisque temperature (usually cone 04 or 06). -

Wax the accent line:

This is crucial for the look: Apply wax resist to the bottom inch of the crock. Also, apply a thin line of wax in the groove underneath the rim if you want raw clay exposure there, or simply wipe the glaze back later. -

Glaze application:

Pour a speckled cream glaze inside the crock, swirl, and pour out. Then, dip the outside into the glaze. The wax at the bottom will repel the glaze, creating that clean line. -

Clean up:

Use a damp sponge to wipe any glaze droplets off the waxed bottom area to ensure a sharp, crisp transition between the white glaze and the toasted clay body. -

Final wipe:

Notice the rim in the photo has a slightly browner tone? You can achieve this by gently wiping the glaze thinner on the prominent edges of the rim, letting the clay body break through during firing. -

Glaze fire:

Fire to the maturation temperature of your clay and glaze (likely cone 5 or 6 for stoneware).

Dual-Tone Effect

To emphasize the rim even more, brush a thin layer of iron oxide wash into the groove under the rim before glazing. This will create a warm, dark shadow line after firing.

Fill your new crock with your favorite wooden spoons and display it proudly on your counter

Lidded Jar With a Satisfying Gallery Fit

This project features a charmingly rustic storage jar with a bulbous, comforting form and a distinctively speckled cream glaze finish. The highlight is the precise gallery fit, which creates a satisfying ‘clink’ when the lid settles into place.

Step-by-Step

Materials

- Speckled stoneware clay (approx. 2-3 lbs)

- Potter’s wheel

- Throwing sponge

- Needle tool

- Wooden rib tool

- Wire cutter

- Calipers

- Trimming tools (loop tool)

- Glossy cream or oatmeal glaze

- Oxide wash (optional for rim/knob)

- Bat mate or clay lugs

Step 1: Throwing the Gallery Jar Body

-

Center the clay:

Start with about 1.5 to 2 lbs of your speckled stoneware clay. Wedge it thoroughly to remove air bubbles, then slam it onto the wheel head. Center the clay into a low, wide mound using firm pressure. -

Open the vessel:

Open the clay down to the bat, leaving about a half-inch floor. Pull the floor out to establish the interior width, compressing the bottom with a rib to prevent S-cracks later. -

Pull the walls:

Begin pulling the walls upward. Aim for a cylinder first, keeping the walls even. Once you have height, gently belly the form outward from the inside using a rib or your fingers to create that round, bulbous shape. -

Form the gallery:

At the rim, you need to create the seat for the lid. Instead of thinning the rim, keep it slightly thick. Use your thumb or a tool to split the rim or push a distinct ledges inwards. This shelf, or ‘gallery,’ needs to be flat and smooth to support the lid. -

Measure immediately:

Before taking the pot off the wheel, use your calipers to measure the exact interior diameter of the gallery shelf. Lock the calipers in place; you’ll need this measurement for the lid. -

Cut and dry:

Wire the pot off the bat and set it aside to dry to a leather-hard state.

Wobbly Lid Syndrome?

If the lid rocks, the gallery or the lid flange isn’t perfectly flat. While leather hard, gently rotate the lid against the jar gallery with a little water to grind them into a perfect match.

Step 2: Creating the Lid

-

Prepare the lid clay:

Center a smaller lump of clay (about 1 lb) on the wheel. You will be throwing this ‘off the hump’ or as a single low puck. -

Throw the flange:

Flatten the clay into a thick disk. Use your caliper measurement to determine the width. You need to throw a flange that extends downwards (which will be upwards when throwing) that fits inside the jar’s gallery. -

Refine the fit:

Check the measurement frequently. The lid’s flange should be just a hair narrower than the caliper measurement to account for shrinkage and glaze thickness. -

Wire off:

Cut the lid from the hump or bat. Handle it carefully to avoid warping the circle, and let it stiffen up alongside the jar.

Step 3: Trimming and Assembly

-

Trim the jar:

Once leather hard, center the jar upside down on the wheel. Trim the bottom to create a neat foot ring that mirrors the curve of the body. -

Trim the lid:

Secure the lid upside down (knob side up) on the wheel. I find using a foam bat or a clay chuck works best here. Trim away excess weight from the top curve. -

Shape the knob:

While trimming the top of the lid, carve out a simple, rounded knob from the center mass. Define the neck of the knob so it’s easy to grip. -

Test the fit:

Gently place the leather-hard lid onto the leather-hard jar. It should sit flush in the gallery without wiggling. If it’s too tight, trim a tiny amount off the lid flange.

Add Texture

Before the clay dries, gently press a uniquely woven fabric or a smooth stone against the belly of the pot while it spins slowly to add subtle visual interest to the plain glaze.

Step 4: Glazing and firing

-

Bisque fire:

Let both pieces dry completely (bone dry) before loading them into the kiln for a bisque fire. -

Wax resist:

This is crucial: apply wax resist to the gallery shelf on the jar and the contact points on the lid. This prevents the lid from fusing to the jar during firing. -

Apply glaze:

Dip or pour a creamy, semi-translucent glaze over the piece. The speckles in the clay will burn through nicely. Wipe back any glaze that got onto the waxed gallery areas. -

Accent the rims:

To get the look in the photo, sponge a little iron oxide or a darker glaze onto the rim of the jar and the knob for a toasted, rustic contrast. -

Final fire:

Fire the piece to cone 6 (or your clay’s maturity temperature). The heat will melt the glaze and reveal the iron speckles.

Enjoy using your new jar for tea, sugar, or storing tiny treasures.

Sugar Bowl or Small Canister Set

Bring the calming colors of the coast into your kitchen with this matching set of lidded jars. Featuring a warm terracotta base, deep ocean blues, and a sandy beige speckled rim, these canisters are perfect for storing sugar, tea, or coffee.

Detailed Instructions

Materials

- Stoneware clay (a speckled buff or warm brown body works best)

- Pottery wheel

- Throwing tools (sponge, needle tool, rib, wire cutter)

- Trimming tools

- Calipers

- Wax resist

- Glazes: Deep Denim Blue, Speckled Cream/Sand, clear glaze (optional)

- Kiln

Step 1: Throwing the Canisters

-

Prepare your clay:

Wedge two balls of clay. For a set like these, aim for about 2-3 lbs for the large jar and 1-1.5 lbs for the smaller one. -

Center and open:

Center the first ball on the wheel head. Open the clay wide enough to create a flat interior floor, compressing it well with your fingers to prevent S-cracks later. -

Pull the walls:

Pull the walls up into a cylinder. Aim for straight, vertical sides with an even thickness. Shape the shoulder slightly inward near the top to give it a classic canister form. -

Create the gallery:

At the rim, use a rib or your finger to split the clay slightly, pressing down to create a recessed shelf (gallery) inside the rim. This is where the lid will sit. Use your calipers to measure the diameter of this gallery seating area exactly. -

Refine and cut:

Smooth the exterior with a rib to remove throwing lines if a smooth finish is desired. Undercut the foot with a wooden knife and wire the pot off the wheel.

Step 2: Creating the Lids

-

Measure twice:

Before throwing the lids, double-check your caliper measurement from the canister galleries. The clay will shrink, so you generally want to throw the lid immediately after the pot so they shrink at similar rates. -

Throw off the hump:

I like to center a large mound of clay and throw the lids ‘off the hump.’ Isolate a small amount of clay at the top, flatten it, and open it. -

Shape the flange:

Create the lid shape upside down. Ensure the outer rim diameter matches your caliper measurement. Creating a slight flange that drops down helps secure the lid. -

Cut and repeat:

Cut the lid off the hump, flip it, and check the fit on the wet canister if you are daring, or wait until leather hard. Repeat for the second jar.

Wobbly Lids?

If your lids rattle, the gallery wasn’t perfectly flat. Use a grinding stone or sandpaper on the bisque ware (or grinding paste on finished ware) to level the contact points.

Step 3: Trimming and Assembly

-

Trim the canisters:

Once leather hard, center the canisters upside down. Trim the bottom to create a clean, flat foot ring, leaving about an inch of unglazed area planned for the bottom. -

Trim the lids:

Place the lids upside down on a chuck or directly on the wheel head (secured with clay lugs). Trim the top to a smooth curve. -

Attach the knobs:

Score and slip the center of the lid. Attach a small ball of clay and throw a simple, tiered knob directly on the lid while it spins slowly. This tiered shape adds a nice tactile element. -

Bisque fire:

Allow all pieces to dry slowly to prevent warping. Load them into the kiln for a bisque fire to roughly Cone 04.

Add Texture

Before the clay dries, use a chattering tool on the cream-colored shoulder area. The glaze will break beautifully over the texture, accentuating the speckles.

Step 4: Glazing

-

Wax the exterior base:

Apply wax resist to the bottom 1.5 inches of the canister’s exterior. This preserves the raw clay band shown in the image. -

Glaze the interior:

Pour a liner glaze (clear or white) inside the canister, roll it around to coat, and pour out the excess. -

Apply the blue band:

Dip the body of the canister into the Deep Denim Blue glaze, going about two-thirds of the way up. Alternatively, you can brush it on. -

Apply the cream band:

Dip the top rim and shoulder into the Speckled Cream/Sand glaze. Let it overlap slightly with the blue to create that interesting transition line. -

Glaze the lid:

Dip the entire top of the lid (holding it by the flange) into the Deep Denim Blue glaze. Wipe the flange where it touches the pot clean of all glaze. -

Final Fire:

Fire to the maturation temperature of your clay and glaze (typically Cone 5 or 6 for stoneware). The overlapped section will melt beautifully.

Enjoy using your new functional art for morning coffee or afternoon tea

Small Pitcher With a Pinched Pour Spout

This charming, rustic pitcher showcases the natural beauty of speckled clay with a creamy, translucent glaze and a toasted rim. Its wide belly and gentle taper create a classic silhouette perfect for serving milk or cream at breakfast.

Step-by-Step Guide

Materials

- Speckled stoneware clay (approx. 1.5 – 2 lbs)

- Potter’s wheel

- Throwing sponge

- Wooden throwing rib

- Metal kidney rib

- Pin tool

- Wire cutter

- Trimming tools

- Bucket of water

- Sponge on a stick (optional)

- Chamois leather

Step 1: Throwing the Body

-

Center the clay:

Begin by wedging your speckled stoneware clay thoroughly to remove air bubbles. Thwap the ball onto the wheel head and center it using firm pressure and high wheel speed. -

Open the form:

Drill your thumb or fingers into the center of the mound, leaving about a half-inch of clay at the bottom for the foot. Open the floor flat, compressing it well to prevent S-cracks later. -

Primary pull:

Slow the wheel down slightly. Perform your first pull to gain height, keeping the walls relatively thick at this stage to support the shaping process. -

Shape the belly:

Using your inside hand to push out and your outside hand to support, gently belly out the bottom two-thirds of the cylinder. Create a voluminous, rounded base. -

Collar the neck:

As you move up past the belly, use both hands to gently collar or choke the clay inward. This creates the tapered neck characteristic of this pitcher style. -

Refine the curve:

Use a wooden throwing rib on the outside while pushing gently from the inside to smooth the contours. I like to emphasize the transition from the wide belly to the narrower neck here. -

Add texture:

While the wheel is spinning slowly, hold the edge of your wooden rib or a modeling tool against the lower belly to create subtle spiral throwing lines or ridges if desired. -

Finish the rim:

Compress the rim with a chamois leather or your sponge. Ensure it is level and sturdy, as this will be the visual focal point.

Step 2: Creating the Spout & Handle

-

Form the spout:

Immediately after throwing, while the clay is still wet, support the neck with one hand. Use the index finger of your other hand to gently pull a section of the rim outward and downward to form a pouring lip. Refine the shape with a wet sponge. -

Wire off:

Run a wire tool under the base to separate the pot from the wheel head. Carefully lift it onto a ware board to firm up to leather-hard. -

Pull a handle:

While the body dries, pull a handle from a separate lug of clay. Aim for a strap-like shape that is wide enough to be comfortable but delicate enough to match the small pitcher. -

Shape the handle:

Curve the pulled handle into a loop and set it aside to stiffen slightly until it holds its shape creating a ‘C’ or question mark curve. -

Trim the foot:

Once the pitcher is leather-hard, center it upside down on the wheel (using a chuck or clay lugs). Trim a neat foot ring, removing excess weight from the bottom.

Spout Drip Check

If your pour spout dribbles, the edge is likely too round. While the clay is wet, sharpen the very edge of the spout with your finger to cut the flow of liquid cleanly.

Step 3: Assembly and Finishing

-

Attach the handle:

Score and slip the attachment points on both the pitcher neck and the handle. Press the handle firmly onto the pot, blending the clay seamlessly with a modeling tool or your thumb. -

Refine the attachment:

Wipe away any excess slip with a damp sponge. Check the alignment to ensure the handle is straight relative to the spout. -

Bisque fire:

Allow the piece to dry completely, slowly covering it with plastic if necessary to even out drying between the handle and body. Fire to bisque temperature (usually Cone 04 or 06). -

Glaze application:

Dip the pitcher into a creamy, semi-opaque white or oatmeal glaze. This type of glaze breaks beautifully over texture and lets the clay specks shine through. -

Wipe the rim:

Immediately after dipping, use a damp sponge to wipe the glaze off the very edge of the rim. This exposes the raw clay body, creating that toasted brown line after firing. -

Final fire:

Fire the piece to maturity (Cone 5, 6, or 10 depending on your clay). Once cool, sand the foot ring smooth with sandpaper.

Pro Tip: Handle Comfort

When attaching the handle, place the top attachment high on the neck. This creates better leverage and balance when pouring a full pitcher.

Now you have a beautifully functional pitcher ready for your morning table

Candle Holder With a Built-In Drip Dish

This project combines functionality with a serene, rustic aesthetic, featuring a wide saucer base to catch melting wax and a sturdy central cup for stability. The speckled clay body and soft matte glaze give it a timeless, handmade feel perfect for cozy evenings.

Detailed Instructions

Materials

- Speckled stoneware clay (approx. 1.5 – 2 lbs)

- Pottery wheel

- Bucket of water and sponge

- Needle tool

- Wooden throwing ribs

- Wire cutter

- Trimming tools

- Measuring calipers

- Standard taper candle (for sizing)

- Matte white or oatmeal glaze

Step 1: Throwing the Form

-

Center the clay:

Begin by wedging your speckled clay thoroughly to remove air bubbles. slammed onto the wheel head and center it into a low, wide puck shape rather than a tall cone, as this will help form the wide base. -

Open the clay:

Open the centered clay all the way down, leaving about a 1/4 inch floor thickness. Instead of pulling the walls straight up immediately, widen the opening significantly to establish the diameter of your outer dish. -

Establish the double-wall structure:

This is the tricky part: split the thick ring of clay into two sections. Use your finger or a tool to create a deep groove about 1.5 inches from the center. You are essentially separating the mass for the inner cup from the mass for the outer dish. -

Pull the outer dish:

Focus on the outer ring of clay first. Pull it outward and slightly upward to form a shallow saucer rim. Use a wooden rib to compress the floor of the dish and smooth the transition to the rim. -

Form the inner cup:

Now, tackle the inner mound of clay. Squeeze it slightly to gather the clay, then open the very center to create the hole for the candle. Pull the walls of this inner section up vertically. -

Refine the candle cup:

Shape the inner cup so it is slightly bulbous at the bottom and tapers slightly in. Leave the distinct throwing ridges on the outside for texture if desired. Check the depth to ensure it can hold a candle securely. -

Measure the fit:

Use your calipers or an actual candle to check the diameter of the central hole. Remember that clay shrinks during drying and firing, so create the opening about 12-15% larger than your standard candle width. -

Final shaping:

Use a sponge to soften all rims. I like to run a metal rib lightly over the outer dish rim to give it that defined line seen in the image.

Shrinkage Math Tip

Make the holder hole roughly 25-28mm wide wet. Standard tapers are ~22mm. Clay shrinks ~12%, making your final fit snug but manageable.

Step 2: Trimming and Finishing

-

Wire off and dry:

Wire the piece off the bat and let it dry to a leather-hard state. This shape can be prone to warping, so ensure it dries evenly and slowly, perhaps under loose plastic. -

Secure for trimming:

Invert the piece onto the wheel head. Because of the central protrusion, you may need a chuck or a foam bat to trim the underside without damaging the candle cup. -

Trim the foot:

Trim a clean, low foot ring on the bottom of the wide dish. This lifts the piece slightly off the table and adds elegance to the silhouette. -

Bisque fire:

Clean up any burrs or sharp edges with a sponge, then load the bone-dry piece into the kiln for a bisque firing. -

Glaze application:

Dip or brush your matte cream or oatmeal glaze. To achieve the look in the photo, let the iron speckles from the clay body burn through by not applying the glaze too thickly. -

Wax the fit:

Be very careful not to let glaze pool inside the candle holder cup, or the candle won’t fit perfectly later. You can wax resist the very bottom of the inner cup. -

Final firing:

Fire to the maturation temperature of your clay and glaze (likely Cone 6 or 10 depending on your materials).

Uneven Drying?

If the rim dries faster than the thick center, the base might crack (S-cracks). Cover the rim with damp paper towel while drying to equalize moisture loss.

Place a flickering taper candle in your new holder and enjoy the warm atmosphere you’ve created by hand

Soap Dish With Drain Holes and a Lifted Foot

Keep your favorite bar dry and long-lasting with this charmingly rustic, oval soap dish featuring functional drainage holes. The speckled stoneware body shines through a subtle white glaze, creating a minimalist piece that looks right at home beside a sunny window.

Step-by-Step

Materials

- Speckled stoneware clay (approx. 1-1.5 lbs)

- Potter’s wheel

- Throwing sponge

- Wire cutter

- Wooden rib tool

- Metal kidney rib

- Needle tool

- Round hole cutter or drill bit

- Loop trimming tool

- Satin white or transparent white glaze

Step 1: Throwing and Altering

-

Center the clay:

Start with a well-wedged ball of speckled clay on your wheel head. Center it low and wide, aiming for a puck shape rather than a tall cone, setting the foundation for a wide dish. -

Open the floor:

Opening the clay down to about 1/2 inch in thickness. This extra thickness is crucial because you will later need to carve into the foot and punch holes through the floor. -

Pull the floor wide:

Pull the clay outward to create a flat plate shape. Compress the floor thoroughly with a wooden rib to prevent stressful S-cracks later during firing. -

Raise the rim:

Pull up a short wall, about 1 inch high. Curve the interior transition from floor to wall gently so it’s easy to clean later. -

Alter the shape:

Cut the clay from the wheel with your wire tool but leave it on the bat. With clean, dry hands, gently squeeze opposite sides of the round form to compress it into an oval shape. Do this while the clay is still plastic but not so wet it collapses. -

Broaden the rim:

Use a soft sponge or chamois to round off the rim, giving it that soft, organic look seen in the photo. I like to smooth it one last time before setting it aside to dry to leather-hard.

Warped Ovals?

If your oval tries to return to a circle during firing, dry it very slowly. Place a small weight on the rim while drying under plastic to help it hold memory.

Step 2: Trimming and Details

-

Secure for trimming:

Once leather-hard, center the oval upside down on the wheel. Since it’s not round, you’ll need to use clay lugs (wads of soft clay) to secure the rim to the wheel head rather than relying on centrifugal force alone. -

Define the foot ring:

Using a sharp loop tool, carve away the excess clay from the outside base to create a defined foot ring. This lifts the dish off the counter, allowing air to circulate. -

Refine the curve:

Smooth the exterior wall with a metal rib to remove grog marks and ensure the outside curve mimics the gentle slope of the inside. -

Mark hole placement:

Turn the dish right-side up. Lightly mark a grid or pattern of dots in the center of the dish where the soap will rest. -

Punch drainage holes:

Use a small circular hole cutter or a drill bit (twisted by hand) to create clean holes through the floor. Support the clay from underneath with your hand to prevent warping as you push through. -

Cleanup edges:

Once the clay is bone dry, use a slightly damp sponge to soften the sharp edges around the drilled holes and the rim. This prevents the glaze from crawling away from sharp corners.

Step 3: Glazing and Finishing

-

Bisque fire:

Load the piece into the kiln for a bisque firing to cone 04 (or your clay’s specific bisque temperature). -

Wax the foot:

Apply wax resist to the bottom foot ring to prevent glaze from fusing the soap dish to your kiln shelf. -

Clear debris:

Check the drainage holes one last time. If any bisque debris is stuck inside, gently ream it out with a needle tool. -

Apply glaze:

Dip the dish into a satin white glaze. A semi-opaque glaze is best here, as it allows the dark iron speckles of the clay body to peek through. -

Clean the holes:

Immediately after dipping, inspect the holes. If glaze has filled them, blow gently or use a tool to clear them so they remain open after firing. -

Final fire:

Fire the piece to maturity (likely cone 5 or 6 for stoneware). Let it cool slowly in the kiln before removing.

Dual-Purpose Design

Make a matching small plate without holes to sit underneath. This catches the drips for surfaces that can’t handle water, like wooden dressers.

Place your finished dish by the sink and enjoy the custom touch it adds to your daily routine

Berry Bowl Colander With Even Perforations

This charming wheel-thrown berry bowl combines functionality with celestial aesthetics, featuring a deep midnight blue interior contrasting against a creamy, speckled exterior. The evenly spaced perforations promote airflow and drainage while creating a playful polka-dot pattern that allows the clay body to shine through.

Step-by-Step Tutorial

Materials

- Stoneware clay (buff or speckled)

- Pottery wheel

- Throwing tools (sponge, rib, needle tool, wire)

- Trimming tools

- Hole cutter or drill bit (approx. 4-6mm)

- Measuring tape or decorating disk

- Deep glossy blue glaze

- Clear or cream matte glaze (optional for exterior)

- Wax resist

- Kiln

Step 1: Throwing the Form

-

Center the clay:

Start with about 1.5 to 2 lbs of well-wedged speckled stoneware clay. Center it firmly on the wheel head, ensuring a stable base for a wide bowl shape. -

Open the floor:

Open the clay to create a curved floor rather than a flat one. This helps berries roll to the center and aids in drainage later. -

Pull the walls:

Pull the walls upward and outward to create a classic hemispherical bowl shape. Aim for a wall thickness slightly thicker than a standard bowl—about ¼ inch—to maintain structural integrity when you punch the holes. -

Refine the rim:

Shape a rounded, smooth rim using a chamois or a piece of plastic. A strong rim is crucial since the bowl will often be handled while wet. -

Define the foot:

Undercut the base slightly with a wooden knife to make trimming easier later, then wire the bowl off the bat and set it aside to dry to a firm leather-hard stage.

Clogged Holes?

If glaze stubbornly fills a hole, use a small twist drill bit (hand-held, not power) to gently ream out the dry glaze before firing. Don’t force it or the clay may chip.

Step 2: Trimming and Perforating

-

Trim the foot ring:

Once leather hard, center the bowl upside down on the wheel. Trim a distinct, elevated foot ring. This lift is essential for a colander so water can drain freely without pooling at the base. -

Smooth the surface:

Burnish or rib the exterior surface to ensure it is completely smooth before you begin cutting holes. -

Mark the grid:

Using a decorating disk or a soft measuring tape, lightly mark a geometric grid or spiral pattern on the exterior to guide your hole placement. Precision here creates the ‘even’ look. -

Punch the drainage holes:

Use a hole cutter or a sharp drill bit to punch holes through the clay at your marked points. Support the wall from the inside with your hand to prevent the clay from warping as you push through. -

Clean the edges:

After punching, small burrs of clay will remain. wait for the pot to dry slightly more, then use a dry sponge or a cleanup tool to smooth the sharp edges of every hole, both inside and out.

Step 3: Glazing and Firing

-

Bisque fire:

Load the bone-dry bowl into the kiln for a bisque firing to prepare it for glazing. -

Wax the foot:

Apply wax resist to the foot ring and any areas where you want the raw clay to remain exposed. -

Glaze the interior:

Pour a deep, glossy midnight blue glaze into the interior. Swirl it quickly to coat the entire inside, then pour out the excess. I find blowing gently into the holes immediately after pouring helps clear them of glaze blocks. -

Clean the exterior holes:

The glaze will naturally drip through the holes. Use a damp sponge to wipe any blue glaze off the exterior surface, ensuring a clean break between the interior color and the exterior. -

Exterior glazing (Optional):

If you want the creamy look shown in the photo, dip the exterior in a sheer white or cream glaze, or leave it bare if using a nice porcelain/white stoneware body. Be very careful to keep the glaze thin so it doesn’t clog the holes. -

Check the holes again:

Before the final firing, inspect every single hole. If glaze has bridged a gap, use a needle tool to clear it. -

Final fire:

Fire the piece to the maturity temperature of your clay and glaze (typically Cone 6 or 10).

Pro Tip: The Rim

Make the rim slightly thicker than usual. Since the walls are perforated, the structural integrity depends heavily on a strong, un-perforated rim to prevent warping.

Now you have a stunning, functional piece of pottery ready to rinse your fresh market finds

Throwing Off the Hump Mini Cup Collection

Create a unified collection of petite, handleless cups perfect for sake or espresso using the efficient technique of throwing off the hump. These vessels feature a charming two-tone aesthetic, contrasting smooth, creamy glaze against the raw, textured warmth of speckled stoneware.

Detailed Instructions

Materials

- 3-5 lbs Speckled Stoneware Clay

- Pottery wheel

- Bucket of water and sponge

- Wooden throwing rib

- Pin tool or needle tool

- Cut-off wire (twisted wire or fishing line)

- Calipers (optional, for consistency)

- Trimming tools

- Cream or antique white dipping glaze

- Wax resist

Step 1: Preparing the Hump

-

Center the mass:

Begin by wedging a large amount of clay—around 3 to 5 pounds—into a cone shape. Secure it firmly to the wheel head. -

Cone up and down:

Center the entire mass of clay by coning it up and pushing it back down. Ensure the base is extremely stable, as this will support multiple pots. -

Isolate the top knob:

Using your hands, squeeze a small section at the very top of your clay cone—about the size of a tennis ball provided you want small cups. This isolated knob will become your first cup.

Step 2: Throwing the Form

-

Open the clay:

Center just that top knob perfectly. Press your thumb into the center to open the floor, stopping about a quarter-inch before the bottom of the knob section. -

Pull the walls:

Gently pull the walls up. Since these are small cups, you may only need one or two pulls. Keep the walls vertical or slightly tapered inward for a modern silhouette. -

Refine the rim:

Compress the rim with a piece of chamois or your sponge to ensure it’s smooth and pleasant to drink from. -

Shape the profile:

Use a wooden rib on the outside to straighten the walls and remove throwing lines if you prefer a cleaner surface. I like to leave a tiny bit of texture to show the hand’s work. -

Define the undercut:

Using a wooden tool or your finger, create a deep groove or undercut at the base of the cup where it connects to the main hump. This marks your cut-off point. -

Cut off carefully:

Take your wire tool or fishing line. Pull it taut and slice through the clay at the groove while the wheel is spinning slowly. Lift the cup gently off the hump and set it on a ware board. -

Reset and repeat:

Re-center the top of the remaining hump and repeat the process until you have a matching set or have used all the clay.

Use Calipers

To ensure your set matches perfectly, set a pair of calipers to your desired diameter. Check the rim of every new cup against the calipers before cutting it off the hump.

Step 3: Trimming and Finishing

-

Leather hard drying:

Let the cups dry to a leather-hard state. They should be firm enough to handle without deforming but still cool to the touch. -

Trim the foot:

Invert the cups on the wheel (using a chum or chuck if necessary). Trim the bottom to create a neat, rounded curve that transitions into the wall. -

Smooth the transition:

Use a damp sponge or a rubber rib to smooth the trimmed area, blending the texture of the trimmed clay with the thrown walls. -

Bisque fire:

Once bone dry, fire the pieces in a bisque kiln to prepare them for glazing.

Add an Iron Wash

For a darker contrast on the unglazed bottom, brush a thin layer of iron oxide wash onto the raw clay before applying the wax resist. This deepens the speckle effect.

Step 4: Glazing

-

Apply wax resist:

This is the crucial step for the look: Apply wax resist to the bottom quarter of the cup exterior and the entire foot. Create a clean, straight line where you want the glaze to stop. -

Prepare the glaze:

Stir your cream or white glaze thoroughly. It should be the consistency of heavy cream to ensure an opaque, even oat-colored coat. -

Dip and clean:

Hold the cup by the foot and dip it straight down into the glaze, submerging it just past the wax line. Hold for 3 seconds, then lift straight out. -

Wipe away drips:

Despite the wax, small beads of glaze might cling to the bottom. Use a damp sponge to wipe the waxed area perfectly clean to reveal the raw speckled clay. -

Final firing:

Fire the cups to the temperature appropriate for your clay and glaze combination (likely Cone 5 or 6 for stoneware).

Arrange your finished set on a wooden tray for a beautifully cohesive presentation

Altered Oval Vase From a Thrown Cylinder

Transform a simple wheel-thrown cylinder into an elegant, almond-shaped vase with this satisfying alteration technique. The finished piece features a creamy, speckled matte glaze that highlights the subtle throwing lines and a warm, exposed clay rim.

How-To Guide

Materials

- Speckled Stoneware Clay (2-3 lbs)

- Pottery wheel

- Medium-sized throwing sponge

- Wooden throwing ribs (straight and curved)

- Pin tool or needle

- Cut-off wire

- Wooden bat

- Chamois leather strip

- Cream/White matte speckled glaze

Step 1: Throwing the Foundation

-

Center and Open:

Begin by wedging your speckled stoneware clay thoroughly to remove air bubbles. Center the clay on the wheel head, then open it up all the way down to the bat, leaving no floor. This is crucial for altering the shape later without cracking the bottom. -

Establish the Base:

Compress the clay ring against the bat to ensure a good seal. Since we are making bottomless cylinder initially, focus on keeping the ring even. -

Pull the Cylinder:

Perform your pulls to raise the walls. Aim for a tall, vertical cylinder with even wall thickness. I find it helpful to cone the clay slightly inward as I get towards the top to maintain control. -

Belly Out:

Once you have your height, use a sponge or curved rib from the inside to gently push the belly of the pot outward, creating a volumetric curve while keeping the neck slightly narrower. -

Refine the Surface:

Use a flexible metal or wooden rib on the outside while supporting from the inside to smooth the walls and accentuate those beautiful horizontal throwing lines. -

Form the Rim:

Collar the neck slightly to define the shoulders. Use your chamois leather to compress and smooth the rim, flaring it out just a touch to create a distinct lip.

Uneven Oval?

If the oval distorts while attaching the base, place a paper template cut to the desired oval shape inside the rim to hold the form while you work on the bottom seam.

Step 2: Altering the Form

-

Release from Bat:

Use your wire tool to slice cleanly underneath the vase to separate it from the bat, but do not lift it yet. -

Wait for Soft Leather Hard:

Allow the piece to dry slightly until it is no longer tacky but still very flexible. If it’s too wet, it will slump; too dry, and it will crack. -

Shape the Oval:

Gently squeeze opposite sides of the cylinder with open palms to compress the circle into an oval. Work slowly from the bottom up to ensure the curve changes evenly. -

Attach the Base:

Roll out a separate slab of clay for the floor. Score and slip the bottom edge of your altered oval cylinder and place it onto the slab. -

Trim and Seal:

Cut away the excess slab around the outside. Blend the seam thoroughly on the outside using a wooden tool, and compress the inside seam with a long-handled brush or stick tool.

Step 3: Finishing Touches

-

Clean the Rim:

Once leather hard, sponge the rim clean to expose the grit and texture of the clay body. -

Bisque Fire:

Dry the piece slowly under loose plastic to prevent the base seam from cracking. Once bone dry, bisque fire to Cone 04 (or your clay’s specific temperature). -

Glaze Application:

Wax the bottom and apply a creamy white matte glaze. Pour the glaze inside, swirl to coat, and pour out. Then, dip the exterior for an even coat. -

Wipe the Lip:

Immediately after dipping, use a damp sponge to wipe the glaze off just the very top edge of the rim. This creates that lovely brown-gold halo effect seen in the photo. -

Final Fire:

Fire the piece to maturity (Cone 5, 6, or 10 depending on your clay). The heat will interact with the iron speckles in the clay, causing them to bleed through the white glaze.

Level Up: Texture

Before altering the shape, lightly chatter or facet the exterior while the wheel is spinning. The oval deformation will stretch these textures in fascinating ways.

Place your sleek new vase on a wooden surface where the natural clay tones can echo the warmth of the surroundings

Marbled Clay Swirl Vase Thrown on the Wheel

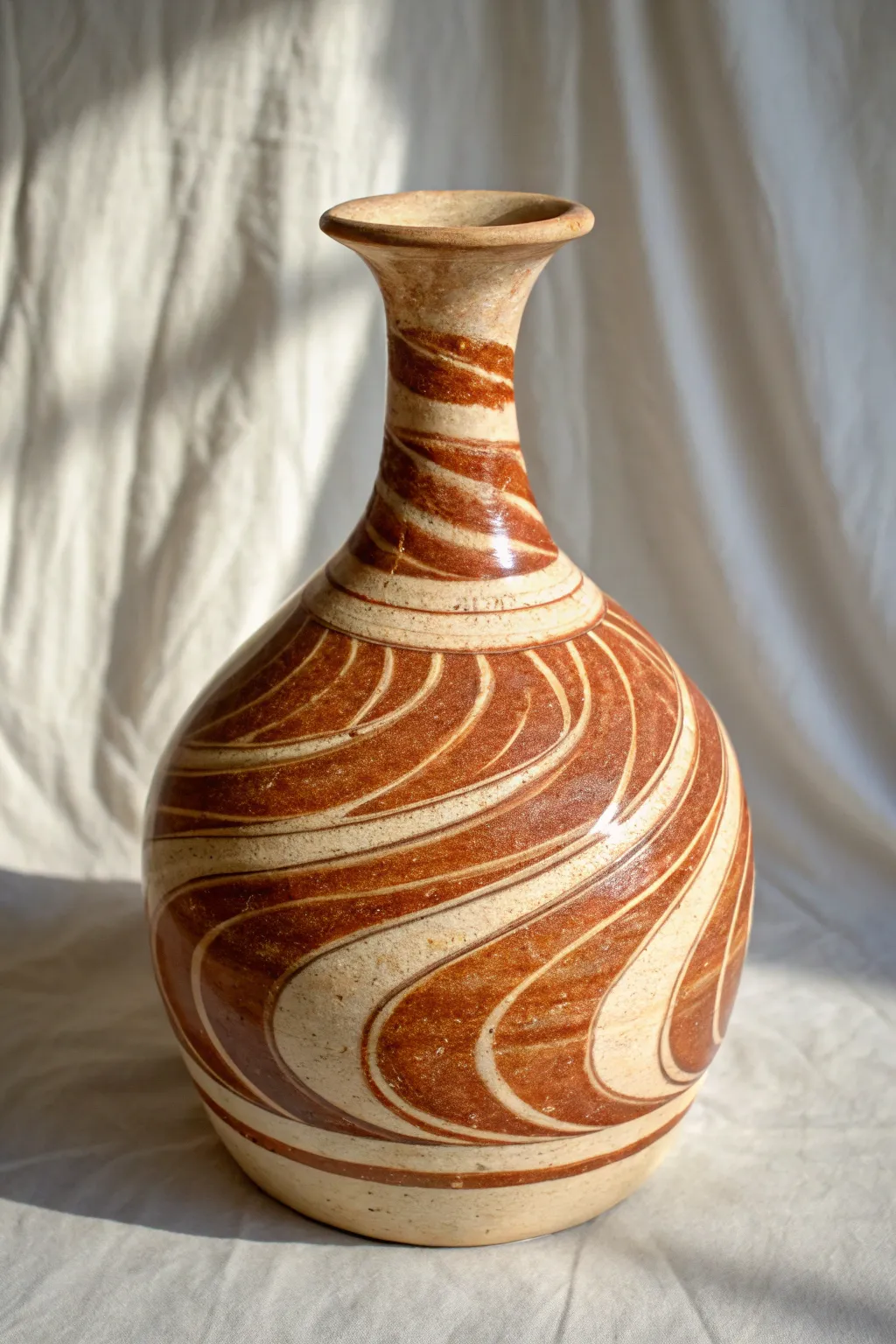

This stunning wheel-thrown vase features a mesmerizing marbled effect created by combining contrasting clay bodies directly on the wheel. The natural swirls of reddish-brown and cream clay dance around the bulbous form, creating a unique, fluid pattern reminiscent of geological strata.

Detailed Instructions

Materials

- High-quality white stoneware clay (smooth)

- Contrasting red earthenware or iron-rich stoneware clay (smooth)

- Pottery wheel

- Water bucket and sponge